If you’re a new homebrewer or considering taking up the hobby, Synergy Brewing Systems would…

Tips for Brewing Lagers

Many new homebrewers start out by making ales as they are currently very fashionable and relatively straightforward to make. Brewing a lager presents a nice challenge for the beginner to intermediate level homebrewer and offers the opportunity to further refine and hone your homebrewing skills. Here are some helpful tips for those looking to brew lagers for the first time or those looking to improve upon their lager homebrew process.

Considerations for Pitching Yeast

Lagers ferment at a much colder temperature than ales which presents a new challenge to homebrewers accustomed to only making ales. Depending on the recommendations for the yeast you decide to use, you will probably need to ferment your lager at a temperature between 45o-55oF. Fermenting lager at room temperatures will lead to extra production of esters which can give a fruity or even spicy flavor to the beer. Good lagers are light in both body and flavor, so flaws such as this are much more noticeable than they are with ales.

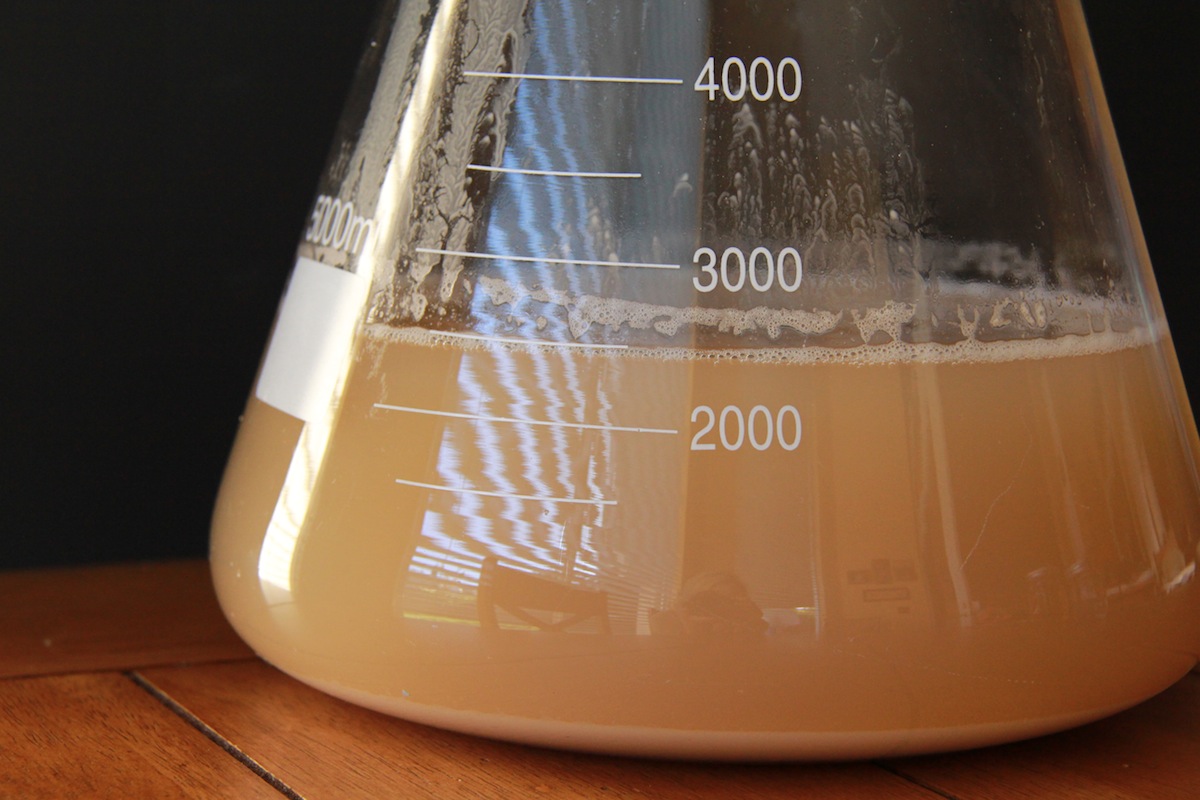

Due to the lower fermentation temperature, it will take longer for your beer to ferment if all other conditions remain the same. To counteract this longer fermentation time, most lagers will require you to use at least two times as much yeast as you would for an ale of the same original gravity.

Many homebrewers pitch into room temperature wort. Since lagers require you to pitch a lot of yeast, there really isn’t a reason for you to pitch it warm, especially since this can cause excess production of esters. Instead, chill your wort to the temperature recommended by the manufacturer of the yeast strain you’re using before pitching the yeast. It’s also a good idea to aerate your wort before pitching the yeast (check out this video tutorial for aerating wort with compressed air) as this will speed up the fermentation process and improve your beer’s flavor.

Diacetyl Rest

Yeasts commonly used for lagers will produce more diacetyl which gives off a butterscotch type flavor. The best way to ensure that all diacetyl is removed from your beer is to turn up the temperature near the end of fermentation. Raising the temperature to anywhere between 60o-65oF and letting it sit for 1 to 3 days should be more than adequate conditions for the yeast to reduce the amount of diacetyl in your lager.

Patience Is a Virtue

“Lager” is derived from a German word meaning “storeroom” or “storage.” “Lagering” is the stage of making a lager after fermentation is complete where the beer is stored at cold temperatures (33o-35oF) for a long period of time. A simple rule of thumb for deciding how long lagering should last is one week for every 10 points of original gravity (a 1.040 lager should sit for 4 weeks). This time will help to clean up your lagers of the various aromas present at the end of fermentation for the crisp, clean taste associated with lagers.

Brewing a lager for the first time can be a daunting process especially if you are a relative homebrew beginner. Hopefully, this article has given you some constructive ideas for improving your lager homebrew. Please let us know if you found this helpful and share your own tips in the comments as well as pictures of any lagers you’ve made with your Synergy Home Brewing System.